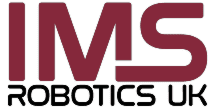

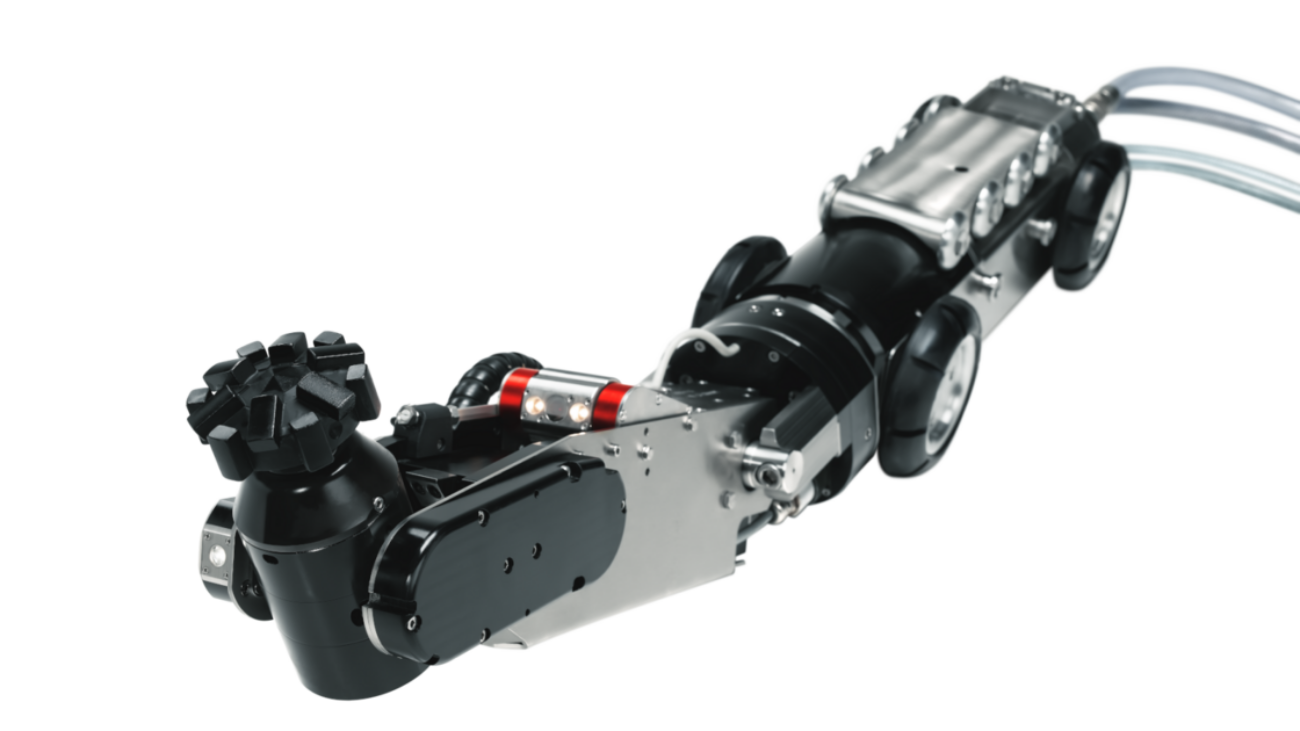

IMS Robotics UK Ltd, a vital part of the IMS Robotics Group, has been steadily growing since its inception back in March 2022. From their headquarters in Leeds, they provide technical service support, rentals, and sales services for an extensive portfolio of cutting-edge products, including house connection cutting robots, main line cutting robots, LED and main line UV curing equipment, as well as ultra-high pressure water jetting technology.

In keeping with their commitment to offer a comprehensive and inclusive range of services to their clients, IMS Robotics UK recognised the need and potential to provide top-quality CIPP materials and consumables to the UK sewer rehabilitation market. As a result, Pro Lining Solutions Ltd (PLS) was established in September 2023 as a subsidiary company of IMS Robotics UK Ltd. PLS is dedicated to facilitating and supplying a wide range of quality CIPP products while maintaining the highest level of customer service and support.

IMS Robotics Group’s mission to be the one-stop shop for all CIPP needs is clear. This expansion is a testament to their steady commitment to this goal.

Pro Lining Solutions Ltd (PLS) will be led by industry experts whom bring a wealth of experience in technical assistance and customer-focused solutions. PLS Management Team adds “we offer well thought solutions to complex problems, focusing on quality and working with clients as partners.”

“The entire team of IMS Robotics UK Ltd and Pro Lining Solutions Ltd. is extremely proud to be a part of the IMS Robotics Group, and we all look forward to a fruitful and exciting future, further developing our market together,” expresses the UK leadership team.

PLS will further strengthen the market presence of the IMS Robotics Group, as well as of other renowned brands in the trenchless industry including Brandenburger Liner GmbH & Co. KG and its GRP lining products, Hurricane Trenchless Technologie GmbH and its lining equipment and all other products and solutions for the industry, as well as Kummert GmbH top-tier sewer inspection products and their industry-leading software. With this last addition, IMS Robotics Group will not only strengthen their position but also enhance their ability to provide a comprehensive suite of solutions to meet the diverse needs of their clients.

Ljubisa Zlatkovic, CEO of the IMS Robotics Group concludes “we are proud of the outstanding first year of our colleagues in the UK. By gaining experienced professionals and establishing PLS, I am convinced that together we will be able to offer the UK market an all-inclusive customer support with comprehensive service.”

For questions kindly feel free to contact:

IMS Robotics Germany: 0049 35205 7555-0 or [email protected]

Pro Lining Solutions: 0113 277 3589 or [email protected]

#IMSUK #IMSGroup #ProLiningSolutions #Expansion #Growth