| Application range | |

| Nominal diameter | - Usable in pipes from DN 200 to DN 800 (inner diameter)

|

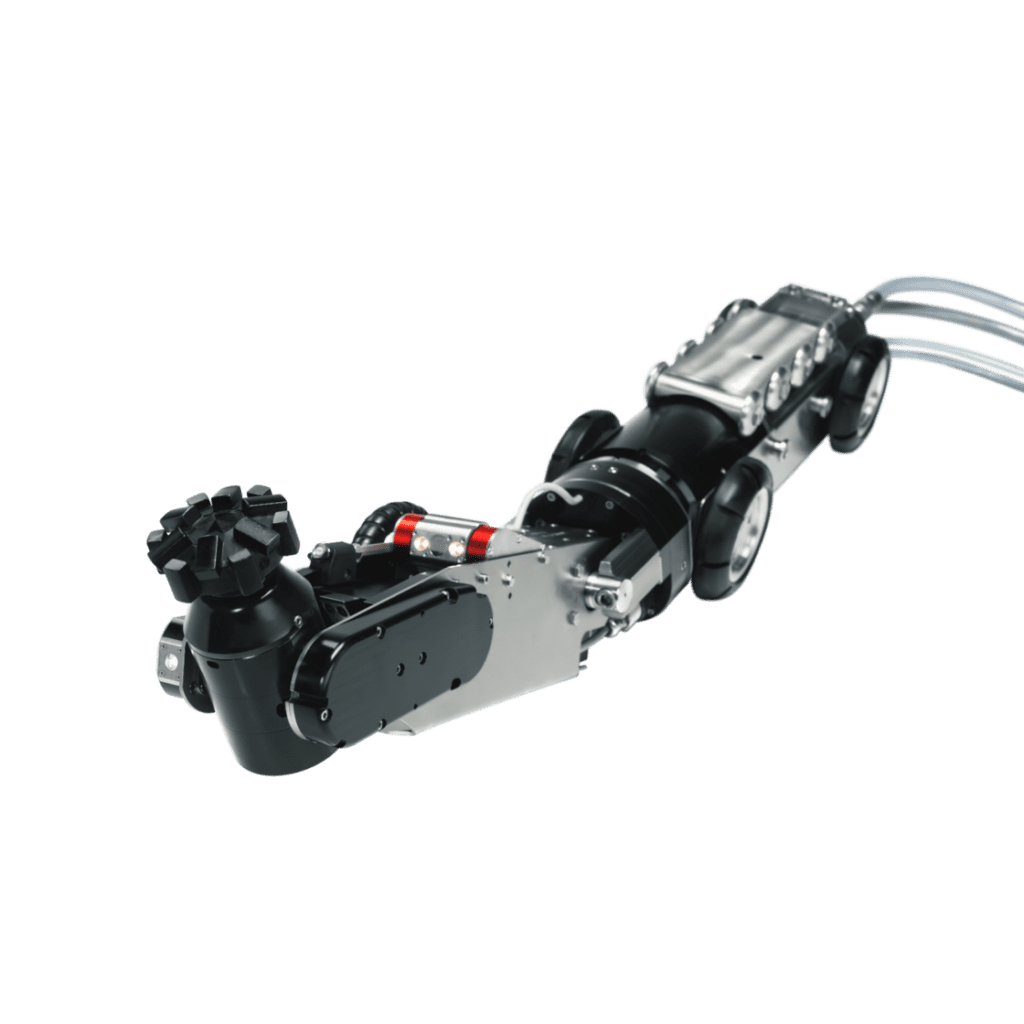

| Components | - Self-propelled carriage, cutting arm, swivel camera, cable drum and control unit

|

| Carriage | - Outer diameter 180 mm

- Dimensions approx. L 1100 mm

- Weight approx. 70 kg

|

| Motor | - Air-powered cutting motor

|

| Camera | - Swivel colour camera with 2 high-power LED and wiper blade

- Rear-view camera with LED illumination

|

| Supply hose length / Cable drum | - 100 m supply hose on cable drum

- Dimensions approx. L 1280 x W 690 x H 1090 mm

- Weight approx. 390 kg with 100 m supply hose length

|

| Control unit | |

| Equipment / Special features | - 400° electrically driven cutting arm rotation

- Approx. 100° swivel movement

- Approx. 120° additional swivel movement cutting motor

- Pneumatic stabilisation for improved traction

- Permanent internal nitrogen pressure monitoring

- Crane connection element

- Combinable with ultra-high pressure (UHP) set IMS CLEANER

- Accessories case

|

| Sensor technology | - Integrated positioning sensors

- Reverse-driving sensor

|

| Further purchase options | - RBO 4 carriage

- Extensions DN 700 to DN 800 (extension carriage)

- Extensions for egg-shaped pipe sections DN 400/600 to DN 600/900

- Self-propelled extension carriage DN 450 to DN 800

- Upgrade from standard swivel head camera to camera with wiper (only with new purchase)

- Additional swivel head camera with wiper

- Ultra-high pressure (UHP) set IMS CLEANER

- Ultra-high pressure (UHP) Rotation-Swivel-Drive and parallel – UHP swivel arm

- Cap relining equipment DN 250 to DN 600

- Connection to SCHWALM installation packer

- Connection to UHRIG Quick-Lock installation packer

- Granulated wheel set D 90 and D 140

- Corundum wheel set D 90 and D 140

-

- RBO 4 cable drum

- Additional control unit cable drum

- Video monitor underneath extension arm cable drum

|