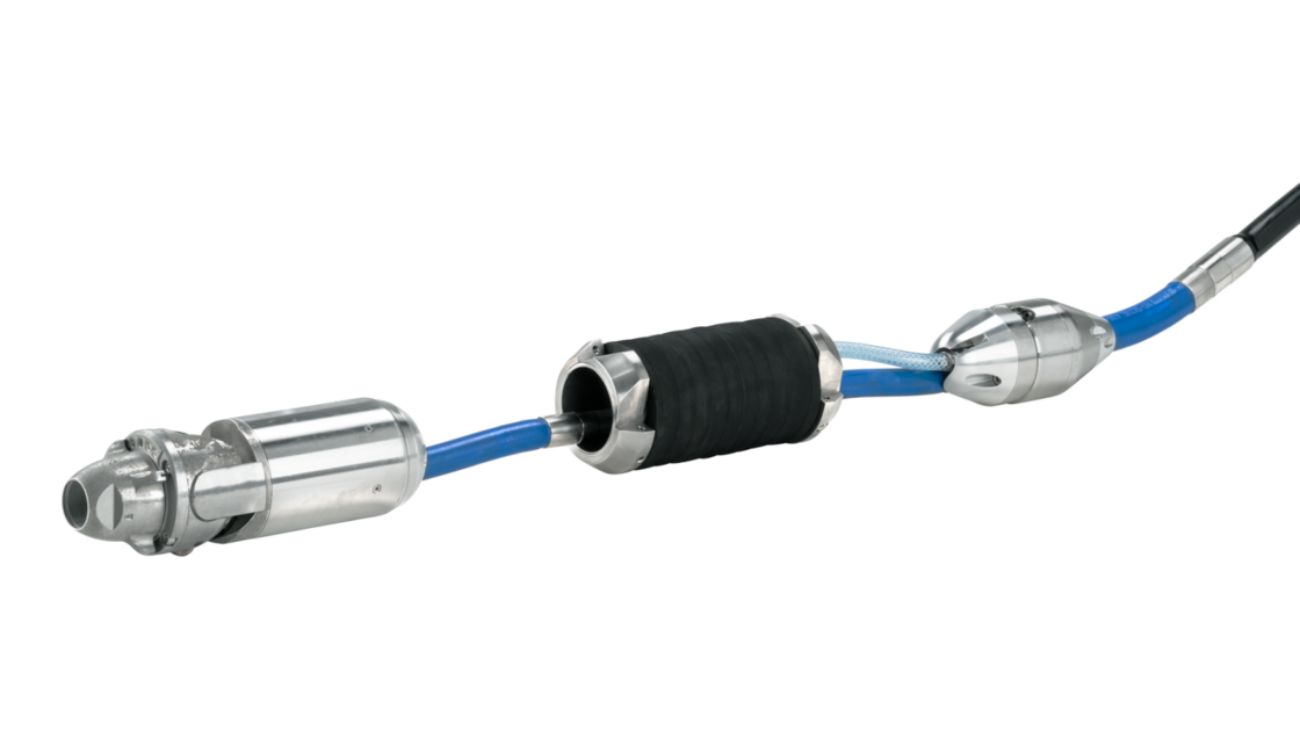

The key to an efficient pipe is ensuring that it’s free and clean from debris, but for it to stay efficient, it needs to be kept on top of to avoid any costly emergencies. High-pressure water pipe technology CLEANERbasic can remove deposits, concrete and other materials with a water pressure of up to 2,500 bar.

Benefits of high-pressure cleaning

Flushes the system

High-pressure cleaning can break up blockages such as grease, sludge, and debris and gets everything running smoothly again.

Good for the environment

Using the water pressure alone can be a good option when being environmentally conscious as it doesn’t use any chemicals, and using water pressure can effectively tackle blockages.

Keeps pipe integrity intact

With no heavy-duty equipment or chemicals needed with High-pressure water pipe technology cleaning, we can keep the pipes’ integrity intact and minimise the risk of pipe corrosion or damage.

Our CLEANERbasic can be used in all pipe materials with diameters from DN 100 to DN 250 with different nozzles to suit whatever jobs you have planned. You can view the product details here if you would like to know more about our CLEANERbasic.

If you want to see a demonstration or rent the equipment, you can have a consultation with a member of our rental park staff, who will be happy to help you.