What is CIPP?

Cured In Place Pipe (CIPP) lining is a way to repair an existing pipe with a textile liner tube and a liquid resin. The process of CIPP lining is non-invasive, as it can be done without digging up the area to fix the pipe, making it environmentally friendly and a popular method to use amongst sewer rehabilitation engineers.

How does it work?

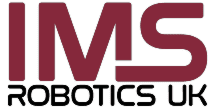

The CIPP lining process is quite a straightforward method. Using robotic cutting tools or ultra-high-pressure water technology, the pipes will be cleaned of debris, tree roots, or blockages so that when the liner is mixed with the resin solution, it can easily be placed into the pipe. Using air pressure, it is blown out so that the lining creates a new pipe within the existing one.

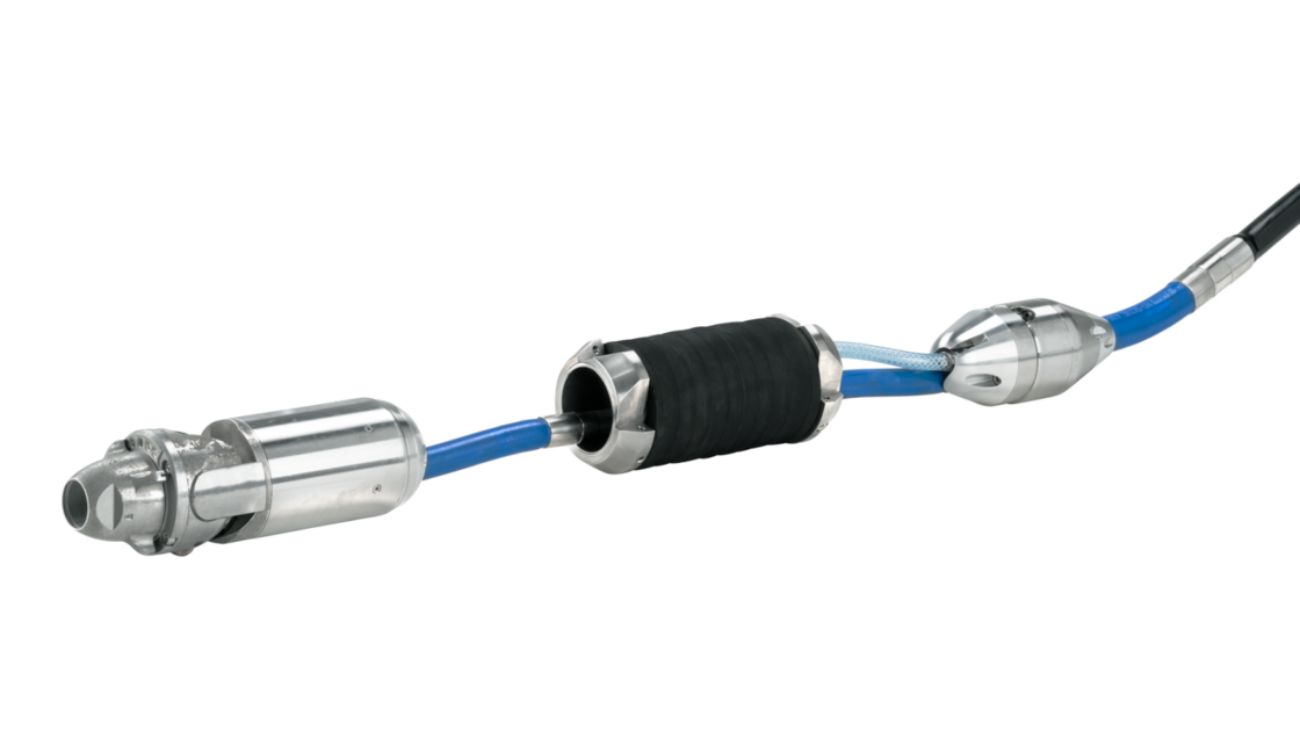

A calibratio犀利士 n tube or a UV curing system is inserted into the newly lined pipe and cured with either hot water, steam, or UV light. Curing the lining hardens the material, making it strong to withstand the necessary hardships.

Once fully cured, if necessary, another robotic cutting tool will then be placed into the new pipe to reinstate any branch line connections within the pipe.

What Tools are used for the CIPP Lining method?

At IMS Robotics, we can recommend the right products you will need for such a job. We can inform you of the best solutions for your CIPP job, from the right cutting tools to UV curing systems. You can also rent the equipment from us if you haven’t got the necessary equipment to hand.

To find out more about how we can help you, get in touch with us, and our team of experts will be happy to help.