There are many advantages of drain relining some more obvious than others so come and check them out.

Damaged drain pipes are a common problem but also a problem that can go unnoticed until it’s too late. Leaky drain pipes are tricky to detect, and by the time they are noticed, the damage to the pipe and the environment, polluting the soil, has been done. usually, this meant excavating the area to replace the pipeline, which could create traffic problems and be an extensive and expensive project.

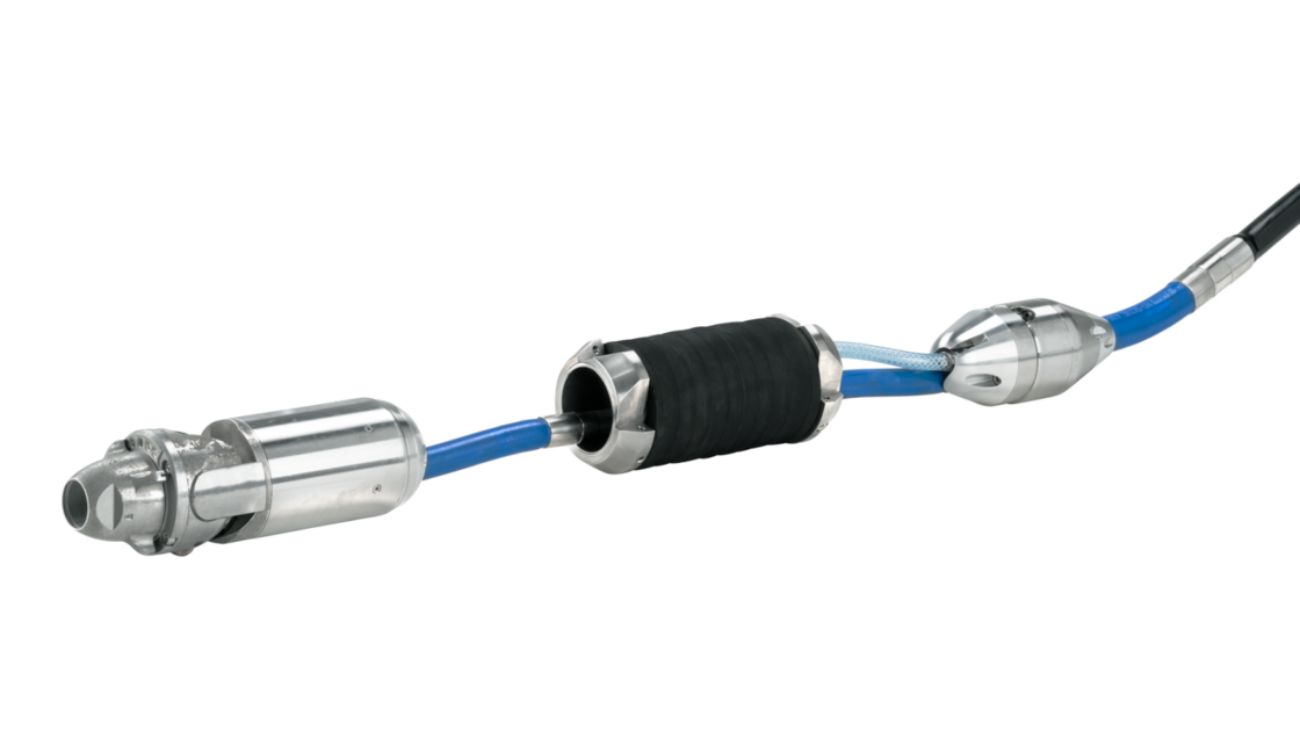

Nowadays, it’s a lot easier to fix these leaking drain problems thanks to modern technology and cheaper. This is where drain relining comes in. Drain relining is a met犀利士 hod used to repair damaged pipes, using a lining fitted into the existing damaged pipe without excavating any groundwork. Drain relining can fix leaks or cracks caused by blockages in the pipes or tree roots that have broken through the pipe, which is more likely to happen with clay drainage pipes. Once the new lining is installed, it’s like a new pipe.

So what are t犀利士 he advantages of drain relining?

Less Expense

With no need for digging up the area, there’s no use for excavation equipment, reducing the cost of equipment and labour.

Minimal Downtime

Drain relining requires less equipment and machinery and no excavation, reducing the disruption to the local area’s daily movements. No roads need to be closed or diverted; they can be done around business trading times, as it is a trenchless rehabilitation method that reduces downtime.

Prevention of Future Leaks and Tree Root Interruptions

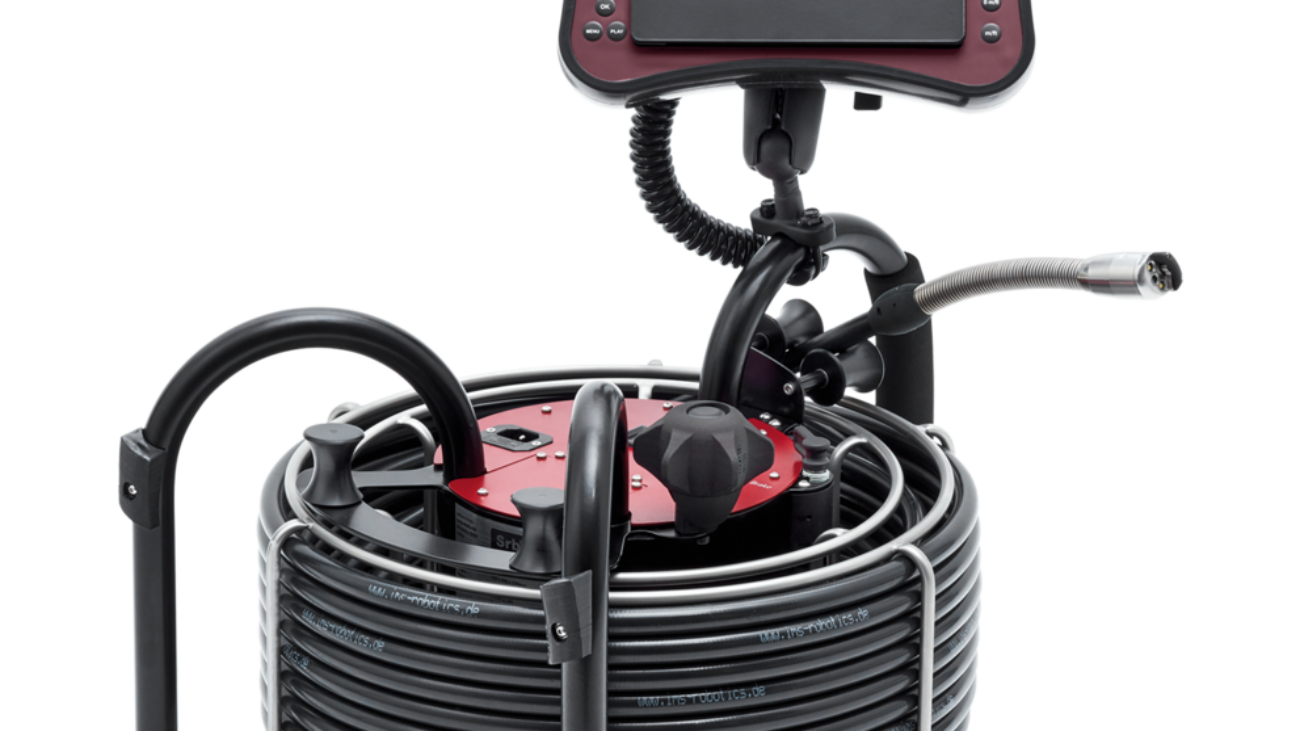

The drain relining works as an extra barrier for any tree roots breaking through the drainage pipes and is an excellent preventative measure. Regular camera drain surveys can also help prevent other leaks, cracks, or intrusions before they become a more significant and costly situation.

Durability

A benefit of drain relining is that it improves the pipe’s structural integrity and has a durability of many years. Regular inspections can extend the life of the drainage pipe even further.

If you have any more questions about the advantages of drain relining then feel free to contact us.