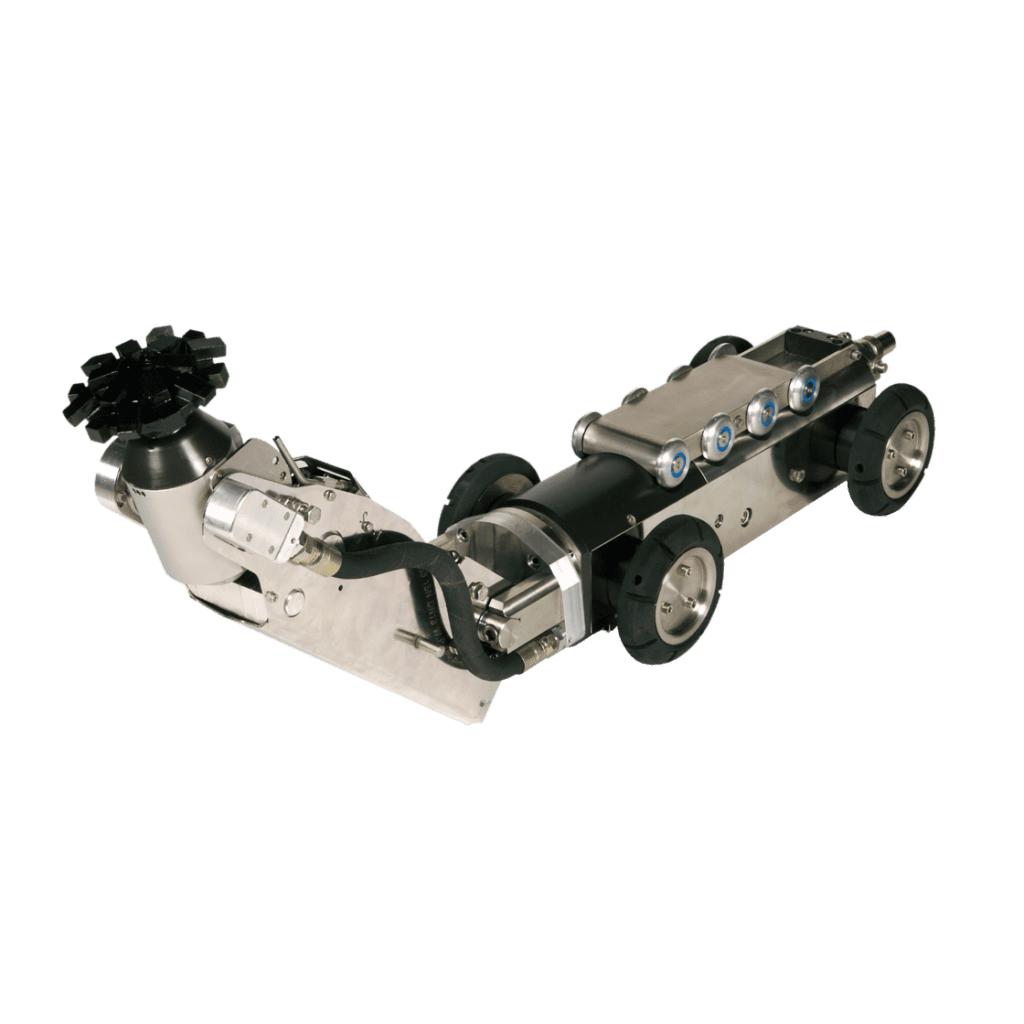

Proven cutting technology for the main sewer

TURBO 3

With the TURBO 3 main sewer cutting robot, you can perform all cutting work in main sewers from DN 200 to DN 600. The device is equipped with an extremely powerful air motor. In addition, the cutting robot can be combined with the IMS rehabilitation system MULTISAN. Various features such as the integrated colour camera with LED illumination, the reverse-driving sensor or the tilt sensor make working with the device easy and effective.

IMS Robotics is a widely known company that specialises in sewer rehabilitation, trusted by many you are in safe hands. We also make sure to put your needs first that’s why we offer servicing and repairs as well as renting & buying so that it makes our robots more assessable to everyone and anyone that needs our services.

The IMS group of companies is there for you worldwide. In addition to our locations in Germany and Switzerland, our sales companies ensure that our customers enjoy the best IMS service wherever you happen to be. We are supported by around 40 dealerships in 30 countries. we are also internationally positioned with subsidiary and affiliated companies in Germany, Europe and beyond.

PRODUCT DETAILS

| Application range |

|

| Nominal diameter |

|

| Components |

|

| Carriage |

|

| Motor |

|

| Camera |

|

| Supply hose length / Cable drum |

|

| Control unit |

|

| Equipment / Special features |

|

| Sensor technology |

|

| Further purchase options |

|

PRODUCT ENQUIRY